| |

ENVIS Technical Report: 93, June 2015 |

|

PATHETIC STATUS OF WETLANDS IN BANGALORE: EPITOME OF INEFFICIENT AND UNCOORDINATED GOVERNANCE |

|

| T.V. Ramachandra* |

Asulabha .K S |

Sincy .V |

Vinay .S |

Bharath H . Aithal |

Sudarshan P. Bhat |

Durga M. Mahapatra |

Energy and Wetlands Research Group, Centre for Ecological Sciences, Indian Institute of Science, Bangalore – 560012, India.

*Corresponding author: cestvr@ces.iisc.ac.in

Citation: Ramachandra T V, Asulabha K S, Sincy V, Vinay S, Bharath H.Aithal, Sudarshan P. Bhat, and Durga M. Mahapatra, 2015. Pathetic status of wetlands in Bangalore: Epitome of inefficient and uncoordinated Governance, ENVIS Technical Report 93, CES, Indian Institute of Science, Bangalore 560012

FOAM AND FIRE : Indicator of contaminants in Varthur & Yamalur - Bellandur Lakes

Cause |

Sustained inflow of untreated sewage (due to BWSSB) and effluents (from industries) due to dereliction of duties by regulatory agencies (KSPCB, CPCB) has contaminated the lake as the inflow of pollutants has surpassed the lake’s assimilative capacity. Froth formation at outlets, profuse growth and spread of marcrophytes are all the indicators of nutrient enrichment. Nutrients in the form of N (nitrogen), carbon (C) and P (phosphorous) enters the lake through untreated sewage. Major part of N is up-taken by plants and algae while phosphorous and carbon gets trapped in sediments. Due to high wind coupled with high intensity of rainfall leads to upwelling of sediments with the churning of water as it travels from higher elevation to lower elevation forming froth due to phosphorous. Discharge of untreated effluents (rich in hydro carbon) with accidental fire (like throwing cigarettes, beedi) has led to the fire in the lake. |

Solution |

-

Decentralised treatment of municipality waste water preferably at ward levels (similar to Jakkur lake)

-

Apply ‘polluter pays principle’ in true spirit - Restrict the entry of untreated sewage and industrial effluents into lakes. Agency responsible for sustained inflow of untreated sewage need to restore the lake. Similarly industries responsible for polluting water bodies should be made to pay (this also entails penalising regulatory agency for dereliction of duties by not applying ‘polluter pays’ principle as per Water Act, 1974)

-

Let only treated sewage through constructed wetlands and shallow algae pond into the lake (as in Jakkur lake)

-

Regular maintenance of floating macrophytes

-

Mapping of water body (identification of flood plain and buffer zone)

-

Remove encroachments near to lakes after surveying the lake area

-

Re-establish interconnectivity among lakes (by removing all encroachers of storm water drains/raja kaluves without any humanity considerations – encroacher or polluter needs to pay for arrogance of encrachments)

-

Planting of native species of macrophytes in open spaces of lake catchment area (for retaining water in the lake)

-

Avoid dumping of solid wastes into lakes

-

Ensure proper fencing of lakes

-

Lake area should not be diverted for any other purposes

-

Make local residents environmentally literate

-

Restrictions / product ban – detergents using phosphorous (which is a limited, non-renewable resource)

|

Foam and Fire: Varthur - Yamalur - Bellandur Lakes

Cause: Sustained inflow of sewage (500 MLD) into Bellandur and Varthur lakes comprises of many natural and synthetic dissolved organic compounds, such as soaps and detergents. These are surface-active agents or surfactants that reduce the surface tension of water, allowing air bubbles to persist at the water’s surface. These detergents essentially consists of phosphates, and a portion of which is up-taken by aquatic plants while the balance gets trapped in the sediments.

Figure 3.1: Foam formation in the outfalls of Bellandur lake a) Initiation of foam formation by entrapment of air at the fall levels of the lake b) Foam piling up due to high flow and mixing c) Foam occupying the entire surface of the channel

Pre-monsoon showers coupled with gusty winds leads to the churning of lake water with upwelling of sediments. Vigorous mixing of surface water coupled with high flow across narrow channels, leading to bubble formation that persist and build up as foam (Figure 3.1 a-c). In the lakes, foam /froth gets accumulated along windward shores. Continuous sewage fed in Bellandur and Varthur lakes, has been witnessing foam at downstream in chocked channels or below fall/discharge point since one decade (Mahapatra et al., 2013a).

Sources of these surfactants: Also, macrophytes and algae inhabiting the lake waters produce many organic compounds (Ramachandra et al., 2009; Mahapatra and Ramachandra, 2013, Mahapatra et al., 2013a,b,c, Ramachandra et al., 2013; Mahapatra et al., 2014), which have surfactant properties. Natural surfactants include carboxylic fatty acids derived from lipids from macrophytes/weeds etc. These are released into water and contribute to a large variety of soluble organic material known as dissolved organic carbon (DOC). Though DOC is produced within lake waters, the major source is the sustained inflow of sewage from the vicinity of the lakes and the watershed. Higher DOC concentrations in lakes, generally impart a brown colour to the water. This highlights that the foam is caused by synthetically produced surfactants released through sewage to surface waters. Synthetic surfactants are widely used in household cleaning products (detergents/soaps), cosmetics and personal care products (shampoo, toothpaste etc.). Common detergents also contains branch-chained alkyl benzene sulfonate surfactants, which are non-biodegradable and results in extremely persistent foam accumulating below the fall levels in the lake and other wastewater outfalls.

Figure 3.2: Distribution of industries in the vicinity of Bellandur and Varthur lake and also industries scattered in the city (overlaid on Google earth image http://earth.google.com)

Detergents and soaps mostly contain phosphate (P) softeners to enhance the effectiveness of surfactants through the reduction of water hardness. P loading in lakes has contributed to nutrient enrichment with the proliferation of cyano-bacterial blooms and macrophytes (aquatic plants). There are set of advanced detergents that exclude phosphates but contain biodegradable linear alkyl benzene sulfonate surfactants, such as sodium or ammonium lauret or lauryl sulfate. Surfactants are also used by many industries (Figure 3.2 and 3.3) as wetting agents, dispersants, defoamers, de-inkers, antistatic agents, and in paint and protective coatings, pesticides, leather processing, plastics and elastomer manufacturing, and oil extraction and production.

Figure 3.3: City map showing the distribution of various industries scattered in the city

Many industries that are present (Figures 3.2 and 3.3) in the upstream of Bellandur and Varthur lakes (Ramachandra and Solanki, 2007) have also contributed to high levels of surfactants in the waters due to the release of untreated effluents in addition to the domestic sewage. These surfactants are very persistent in the environment, bio accumulate in organisms and humans with various biological consequences. Alkyl phenol ethoxylates for example, which continue to be widely used by industry, have been shown to have estrogenic properties eliciting reproductive effects in fish and other organisms. Similarly, per-fluoro octanoic acid and per-fluoro octane sulfonate, which were commonly used in the production of stain resistant and non stick coatings including Scotch guard and Teflon, also have estrogenic and carcinogenic properties. In contrast to natural foam, fresh detergent based foam is of white colour with noticeable odour. Bellandur and Varthur lake have been receiving a mix of untreated and partially treated wastewaters (~500 million litres per day, MLD), from major residential areas and some industries, both synthetic and natural compounds that are present have contributed to the formation of foam.

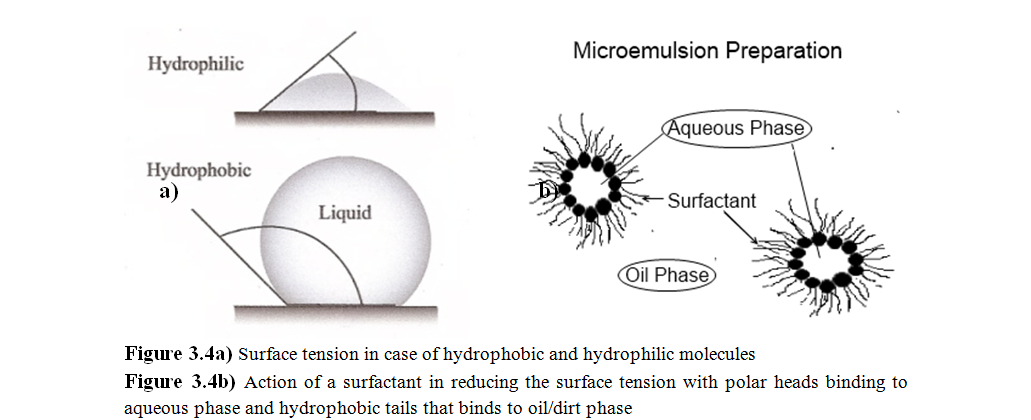

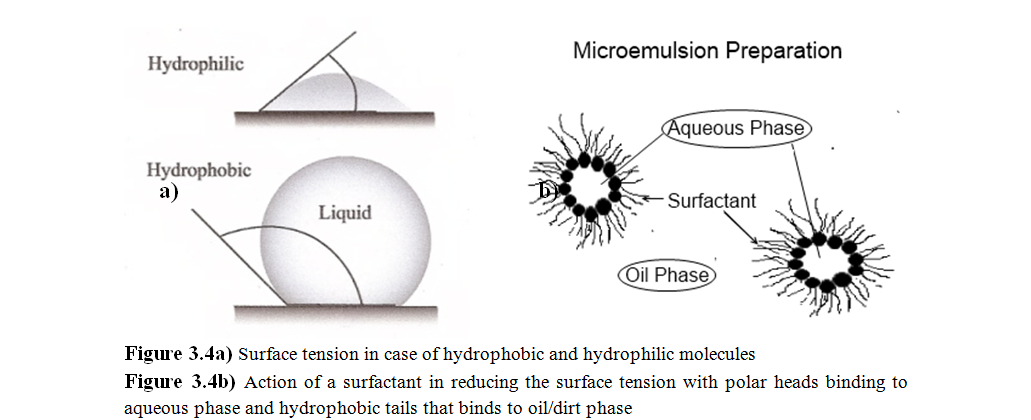

Surfactants influence on the surface tension of water:

Surface tension is an important property of water. It results from cohesion – the attraction of water molecules for one another. Cohesion gives water the ability to form droplets and contributes to the formation of waves and currents, which play an important role in the distribution of temperature, dissolved gases, nutrients, micro-organisms and plankton. At the surface of the lake (i.e. the air-water interface), cohesion creates a thin ‘film’ or tension. This allows insects like water striders to ‘walk’ on water and forms a special habitat for some aquatic organisms adapted to living on this surface film (mosquito larvae for example). Surfactants are amphipathic molecules, that is, they contain both hydrophilic (water-attracting) and hydrophobic (water-repelling) components. The hydrophilic component can form bonds with water and competes with other water molecules as they attract one another (Figure 3.4 a). In this manner, surfactants reduce the overall attraction between water molecules, thus diminishing surface tension (Figure 3.4b). Lower surface tension causes water to become more ‘fluid’ or elastic, and when air gets in the resulting bubbles can persist for some time.

Figure 3.5: Foam formation at the a) Varthur North (Kodi) outfalls, b) South outfalls

Foam / Froth formation:

Surfactants have contributed to 50% of foaming due to a reduced surface tension and balance is due to the intrusion of air into these waters to form the foam bubbles. In the studied lakes wind-induced currents and incipient waves cause turbulent mixing of air and water. Foaming often increases during runoff and rainstorms that transport the surfactants. Figure 3.6 illustrates hydrophobic oil and aqueous phases.

Figure 3.6 a) Hydrophobic oil phase (non polar tails towards the centre) b) Aqueous phase (polar heads to wards the centre)

Characteristics of foam:

The foam collected from the Varthur outfalls were white in colour with a greasy/oily dark materials sticking on the surface of the foam bubbles (Figure 3.7). The foam had a pungent odour with sulphide smell unlike the natural foam that has an earthy or fishy aroma. These white foams progressively turn off-white and then settle as dark grey residue over time. Experiments conducted in laboratory shows, the persistent nature of the foam that lasts up to 6 days (Figure 3.8).

Figure 3.7: Foam sample collection from Varthur north outfalls

The analysis conducted on foaming abilities showed, mean bubble size decrease with time, and finally ends up in sizes < 2 mm in diameter. The initial bubble sizes range from 2-4 cm (Figure 3.9). Moreover, the foam volumes were observed to be higher during the 2nd and 3rd day that correlated with the mean bubble size. The foam diminishes after the 6th day due to low stability. Earlier reports on wastewater systems have indicated onset of foaming is because of surfactants and bio-surfactants, abundant in wastewater and sludge. They have both hydrophobic and hydrophilic properties and tend to accumulate at air–liquid interfaces increasing surface activity. When air/gas is introduced into solution, a thin liquid film is formed around the gas bubbles as they reach the air–liquid interface preventing them from bursting (Hug, 2006 and Ganidi et al., 2009). The foaming persistence tests carried out in the laboratory by stirring showed the presence of surfactants indicating highest foaming abilities. The liquid phase of the foam samples contained significant amounts of surface active groups during the analysis period. However the foaming potential decreased after 4 days this can be attributed to the decrease in the interactions between solid particles and the surfactants and hence the stability of the foam. Studies on wastewater systems highlights that sludge, (Mahapatra et al., 2013a) containing surfactants and the foaming potential is enhanced or reduced depending on the surfactant–surfactant and particle–surfactant interactions (Glaser et al., 2007 and Eisner et al., 2007). More importantly increase of temperature in liquids containing surfactants result in increased surface activity (lower surface tension) enhancing the foaming potential (Barber, 2005) which was also observed in the present study as the foaming events are periodic and are often noticed during the summer at lake outfalls. In order to gain a better understanding of foam creation and stabilization, the liquid phase of foams generated at the outfalls of Varthur lake was analysed for carbon assays as COD, BOD and solids. The BOD and COD values were ~0.6 g/l and 1.14 g/l respectively. High total solids (TS) of ~110 g/l were observed in the liquid phase of the foam sample out of which ~92 g/l were total volatile solids (TVS). The ash content was ~16.2 g/l and the total dissolved solids (TDS) were ~7 g/l.

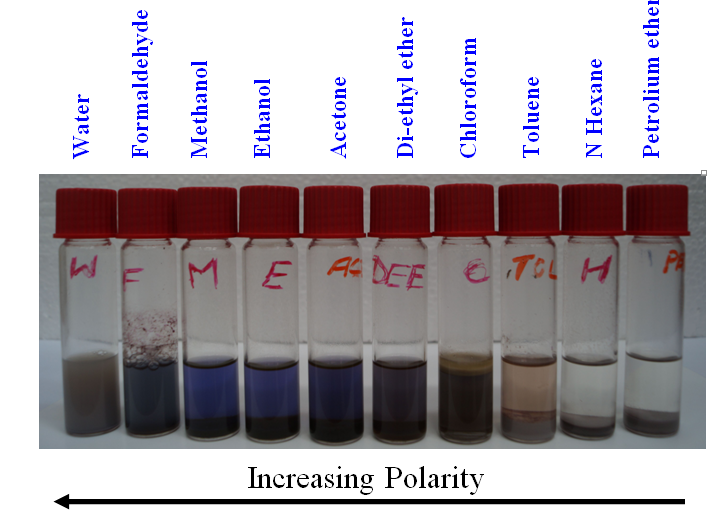

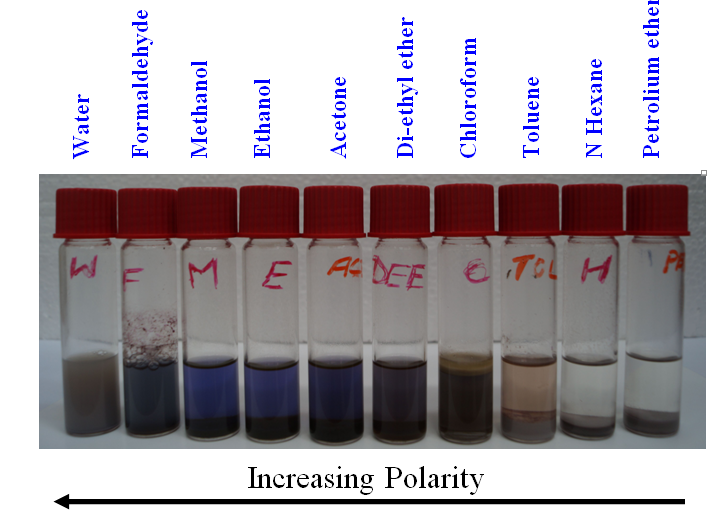

Figure 3.8: Analysis of Elution of the liquid phase of the foam in different solvents in the order of increasing polarity

Figure 3.9: Foaming coefficients– foam volume and mean bubble size variation with time (note 1-12 indicates 6 days’ interval)

Hydrophobic compounds present in the DOC foam were confirmed by eluting the foam in non-polar and polar solvents (Mahapatra et al., 2013a-c; Mahapatra et al., 2014a,b). The solvents comprised of water, formaldehyde, methanol, ethanol, acetone, di-ethyl ether, chloroform, toluene, n-Hexane and petroleum ether that were arranged in order of decreasing polarity. The results showed the presence of amphipathic molecules as shown in Fig. 8. The analysis showed presence of both polar and non polar compounds in the liquid phase of the froth. The froth analysis showed higher values of TP >2 g/l with orthophosphate values >75 mg/l indicating higher P content in waters owing detergents and also P up-welling due to anaerobic conditions in the sediment layer of the lakes, aided my macrophyte cover over the lake surface. Laboratory analysis of the commonly used detergents as Surf Excel, Ariel, Rin etc. showed higher presence of poly phosphates (27-34 %) and TP (~20-25 %) indicating detergents rich in P. Earlier studies on sludge sediments in Varthur lake indicated greater P influx from sediments during anaerobic conditions mostly during summer. The organic matter settled in the bottom of the lake resuspends owing to change in redox environment, that up-wells large quantities of immature sludge which imparts the dark grey colour to the lake water. Consequently, the water at the outfalls were grey in colour with higher particulate matter arising from sludge.

Influence of water hardness on foaming:

Water hardness influences the amount of foam that results from water turbulence. Water hardness is a result of the presence of certain minerals in water, principally calcium and magnesium (and iron and manganese, to a lesser extent). Dissolved in water, calcium and magnesium exist as positively charged ions. These out-compete water molecules for binding to negatively charged surfactants (carboxylic fatty acids for example). The harder the water, the more likely the surfactant will be bound up by calcium or magnesium and, consequently, the less likely surface tension will be reduced. The Bellandur and Varthur lake waters are moderately hard waters (~215 mg/l of total hardness), with high Ca and Mg concentrations. As a result, foaming is not usually excessive in these waters. The incidence of high foam is also associated with high Na content in the lake in comparison to Ca and Mg. When the water is soft foam may occur more frequently.

Foam is usually harmless if they are only from vegetative origin where the foaming agents are primarily proteinaceous or carbonaceous matter. In this case only a small amount of fatty acids or other foaming agents are required to produce foam. Only about 1% of the foam is made up of the foaming agent, the remaining 99 % being air and water. The foams originating from the wastewaters, detergents and other industrial origin surfactants will have significant impacts to the aquatic ecosystem and human health. These foam can accumulate compounds that are repelled by water (hydrophobic), so foam can be enriched significantly with particulate organic and inorganic compounds such as nutrients (N, P, C), cations (K, Na, Ca, Mg), heavy metals (Cd, Cu, Fe, Pb, Zn) and chlorinated hydrocarbons. Therefore when these foams get in direct contact with human beings, depending on the specificity, they can cause many stimulatory effects that can trigger the immune response in the body. Moreover, the organisms that inhabit the surface layer would be more exposed to these contaminants and this could form a pathway to introduce contaminants into the food web.

Fire associated with foam in Yamalur- Bellandur lake

Flammability is the ability of a substance to burn or ignite, causing fire or combustion. Incidence of foam catching fire (Fig ure 3.10a and b) are due to compounds with high flammability i.e. mostly hydrocarbons and organic polymers from nearby industries in the vicinity of Bellandur lake. High wind coupled with high intensity of rainfall leads to upwelling of sediments with the churning of water as it travels from higher elevation to lower elevation forming froth due to phosphorous. Discharge of untreated effluents (rich in hydro carbon) with accidental fire (like throwing cigarettes, beedi) has led to the fire in the lake.

Figure 3.10 a) Flames over the surface of the froth during the night observed at the Yamalur-Bellandur lake outfalls b) Flames due to the residual black (oily/greasy materials – heterogenous phase) on the surface of the foam

The foam is a very periodic event (annual) which happens mostly in the pre-monsoon period at the outfalls of Bellandur and Varthur lake (Mahapatra et al., 2013a). The foam built up at the dry periods can be attributed to churning and associated sediment re-suspension from the lake bottom. This phenomena is also triggered due to anaerobic environments in the sediments that leads to a reducing environment (-340 to -280 mv – oxidation reduction potential; ORP; Mahapatra et al., 2013a-c) where the sludge/sediment bound P along with the decomposed plant parts, oil and greasy materials gets resuspended in the water (Mahapatra et al., 2013a,b). This produces a solid black layer on the surface of water that comprise of macrophyte/plant derived organic acids. With high wind velocities and water flow, this black particle that is mostly soluble in oil phase (hydrophobic in nature) gets deposited on the surface of the foam or bubbles. Frequent aeration of the lake waters falling off from the outfalls via splashing, forms gas bubbles that increase the liquid interfacial area a here at times charging occurs. Apart from charge generation at the surface, continuous aeration aids in formation of persistent froth that lasts from hours – days. This foam is also the source of very fine mist as it bursts. The rate at which the bubble bursts is dependent on the static spark that helps in disruption of the foam.

References:

-

Barber, W.P. (2005). Anaerobic digester foaming: causes and solutions. Water 21, 45–49. Available from: http://www-uk1.csa.com/ids70/results.php?SID=4oo9hnkld4c223a8lr72q3vbb1&id=2

-

Ganidi, N., Tyrrel, S., Cartmell, E. (2009). Anaerobic digestion foaming causes – a review. Bioresource Technol. 100, 5546–5554.

-

Hug, T. (2006). Characterisation and controlling of foam and scum in activated sludge systems. Swiss Federal Institute of Technology, Zurich.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V. (2011c). C:N ratio of Sediments in a sewage fed Urban Lake. International Journal of Geology. 5,3:86-92.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V. (2011a). Assessment of Treatment capabilities of Varthur Lake, Bangalore. International Journal for Environment, Technology & Management. 14, 1-4:84-102.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V. (2013a), Bioenergy generation from components of a Continuous Algal Bioreactor: Analysis of Lipids, Spectroscopic and Thermal properties. Proceedings of 10th IEEE INDICON Conference on Impact of Engineering on Global Sustainability, pp. 183-184, IIT Bombay, India 12th – 15th Dec, 2013.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V. (2014a), Bioremediation and Lipid Synthesis of Myxotrophic Algal Consortia in municipal wastewater. Bioresource Technology. 168: 142-150.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V. (2014b), Novel Algal Bioreactor for Wastewater Treatment and Biofuel (lipid) Production. GYTI Technological Innovations, SRISTI pp. 60, GYTI Exhibition, IIM Ahmedabad. India 29th March, 2014.

-

Mahapatra D.M., Chanakya H.N., Ramachandra T.V., (2011b). Role of Macrophytes in urban sewage fed lakes. Institute of Integrative Omics and Applied Biotechnology. 2, 7: 1-9.

-

Mahapatra, D.M., Chanakya, H.N, Ramachandra, T.V. (2013b). Euglena sp. as a Suitable Source of Lipids for Potential use as Biofuel and Sustainable Wastewater Treatment. Journal of Applied Phycology. 25:855-865.

-

Mahapatra, D.M., Chanakya, H.N., Ramachandra, T.V. (2013c). Treatment efficacy of Algae based sewage treatment plants. Environmental Monitoring and Assessment. 185:7145-7164.

-

Mahapatra, D.M., Ramachandra, T.V. (2013). Algal Biofuel: Bountiful Lipid from Chlorococcum sp. proliferating in Municipal Wastewater. Current Science. 105:47-55.

-

Ramachandra T.V., Solanki, M. (2007). Ecological assessment of Lentic Waterbodies of Bangalore, ENVIS Technical Report 25, Environmental Information System, Centre for Ecological Sciences, Bangalore.

-

Ramachandra T.V. and Murthy R. (2000). Restoration and management strategies for wetlands, Lake Symposium 2000.

-

Ramachandra, T.V., Mahapatra, D.M., Karthick B., Gordon, R. (2009). Milking diatoms for sustainable energy: biochemical engineering vs. gasoline secreting diatom solar panels. Industrial & Engineering Chemistry Research. 48, 19:8769-8788.

-

Ramachandra, T.V., Mahapatra, D.M., Samantray, S., Joshi, N.V. (2013). Biofuel from Urban Wastewater: Scope and Challenges. Renewable and Sustainable Energy Reviews. 21:767-777.

Foam and Fire in Varthur & Yamalur - Bellandur Lakes: Highlights the level of irresponsibility of para-state agency responsible for handling sewage in the city.

|

|